Monitoring Where It Matters Most

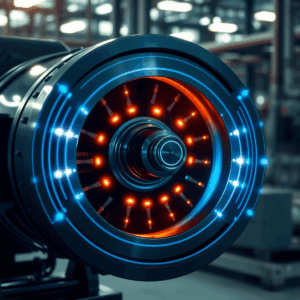

In industrial environments, temperature is often the first sign of trouble. But when it comes to rotary machines—like electric motors and generators—monitoring the most critical parts isn’t always easy.

At Kliskatek, we’re helping manufacturers go beyond traditional monitoring by embedding batteryless wireless temperature sensors directly into rotating components. The result? Smarter machines, longer lifespans, and more efficient factories.

The Rotor Challenge

Monitoring the stator of an electric motor is straightforward—wired sensors work just fine. But the rotor, which spins at high speed, is a different story. Wires aren’t an option, and battery-powered sensors are impractical due to maintenance costs and reliability concerns.

That’s where battery-free wireless sensors come in. Powered by RF energy harvesting, these sensors operate without batteries, enabling real-time temperature monitoring of rotating parts (or current, or voltage…) —without ever needing to stop the machine.

Why It Matters: Permanent Magnet Motors

Many modern motors use permanent magnets for their efficiency and compact size. But these magnets are sensitive to heat—exceeding critical temperatures can cause irreversible demagnetization, leading to performance loss or failure.

Traditionally, designers overcompensate by oversizing magnets to tolerate worst-case scenarios. But with real-time temperature data from embedded sensors, you can:

- 🧲 Optimize magnet sizing, reducing material costs (especially rare earths)

- 🔥 Prevent thermal damage, extending motor life

- 🏭 Enable predictive maintenance, reducing downtime and manual inspections

Beyond Temperature: A Platform for Condition Monitoring

While temperature is a key metric, it’s just the beginning. Today’s batteryless sensor platforms can also monitor:

- 📈 Vibration and acceleration (detect imbalance or bearing wear)

- 💧 Humidity and condensation (prevent corrosion)

- 📊 Pressure and strain (monitor load and stress)

- ⚡ Voltage and current (monitor electrical performance)

- ⚙️ Actuation (trigger relays or alerts autonomously)

Combined with edge analytics and digital twin models, these sensors enable real-time diagnostics and control, even in the most challenging environments.

Ambient IoT for Industrial Resilience

This is Ambient IoT in action: invisible, maintenance-free intelligence embedded directly into machines. No batteries. No wires. Just actionable data—delivered exactly when and where it’s needed.

At Kliskatek, we’re building sensing systems that don’t just monitor—they empower smarter decisions across the factory floor.

Final Thoughts

Rotating machines are the heartbeat of industry. By embedding batteryless sensors into their most inaccessible parts, we’re unlocking a new era of predictive, efficient, and resilient manufacturing.

Let’s stop guessing—and start sensing.