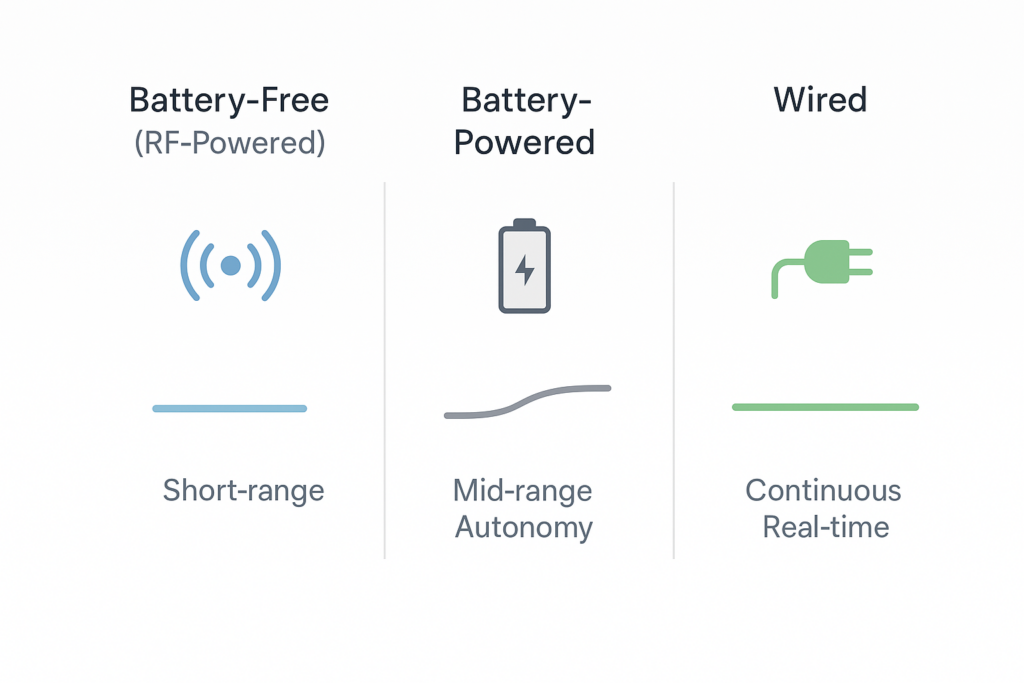

How battery‑free, battery‑powered, and wired architectures each play a role in building scalable, long‑life sensing systems.

Maintenance has always been the hidden cost of industrial sensing. Batteries, wiring, site visits, replacements, downtime—each small in isolation, enormous at scale. As IoT deployments grow from hundreds to tens of thousands of nodes, the biggest challenge isn’t the sensor technology itself. It’s how to keep all those sensors alive.

This is why zero‑maintenance sensing—systems designed to operate for years with no battery replacements, no field servicing, and minimal intervention—is becoming one of the most important evolutions in industrial IoT. Market research shows battery‑free sensors alone are expected to grow from USD 73.2 M in 2025 to USD 512.8 M by 2035, driven by IoT expansion, sustainability demands, and ultra‑low‑power electronics. Analysts further highlight that these sensors reduce electronic waste and support green initiatives across industrial automation, smart cities, agriculture, and environmental sensing.

But here’s the key insight:

Zero‑maintenance is not one technology. It’s a strategy.

And depending on the physical realities—distance, geometry, duty cycle—you may achieve it through battery‑free, battery‑powered, or wired sensing.

At Kliskatek, we design with all three. We prefer battery‑free when the geometry allows it, but we recommend the architecture that will truly deliver long‑life, low‑touch performance.

Let’s explore when and why each one makes sense.

1. Battery‑Free (RF‑Powered) Sensors: Zero‑Maintenance When Geometry Allows

Battery‑free sensors use NFC, HF, or UHF (RAIN RFID) to harvest energy from a nearby reader. They are ideal when you can bring the reader close to the sensor—handhelds, fixed positions, mobile readers, or even drones.

RAIN RFID–based sensing is rapidly growing because it provides maintenance‑free, battery‑free operation over several meters using standard EPC Gen2 / ISO 18000‑63 infrastructure. Passive RAIN sensors offer cost‑effective sensing for moisture, temperature, strain, and other parameters, enabling ubiquitous, low‑touch sensor networks.

Where battery‑free excels

Battery‑free is ideal when:

- The reader can get close (centimeters to a few meters).

- The update frequency is low (minutes → days → weeks → monthly).

- The structure is remote, old, or unpowered.

- The sensing needs are slow‑changing (strain drift, moisture, creep, corrosion).

- Long operational life (decades) is required.

Examples

- Rotating machines

Readers can be placed close to the rotor or housing; energy transfer is reliable. - Data centers

Existing RAIN readers already present → sensors piggyback on this power and infrastructure. - Bridges, tunnels, rural structures

This is where the nuance matters:

Most bridges do not need real‑time data. Monthly or quarterly data is sufficient for corrosion, humidity, strain evolution, freeze–thaw cycles, etc.

Battery‑free sensors combined with drone‑mounted UHF RFID readers offer a zero‑maintenance retrofit option for bridges with no wiring, no power, and limited access.

In fact, because old or remote bridges often lack reliable power and are expensive to retrofit, battery‑free becomes the only viable option for long‑life structural sensing.

2. Battery‑Powered Sensors: Zero‑Maintenance When Autonomy Is Needed

Battery‑powered wireless sensors fill the gap between “reader must be near” and “continuous wired monitoring.” When distances are too long or unpredictable for RF energy harvesting, but the data rate is still moderate (minutes or hours), battery‑powered nodes provide multiyear autonomy and predictable operation.

Market reports show that battery‑free sensors are growing fast, but battery‑powered solutions still dominate deployments requiring higher duty cycles, longer ranges, or intermittent connectivity, especially in industrial and environmental monitoring.

Where battery‑powered excels

- When the reader cannot reliably reach the sensor.

- When some periodicity is required (every hour, daily).

- When update intervals are shorter than viable RF‑harvest intervals.

- When installation needs to be simple, but access is difficult.

This is often the case in:

- mid‑span bridge elements

- tunnels where RF propagation is poor

- environmental monitoring on slopes or embankments

- long‑range outdoor deployments where drone access is limited

Battery‑powered does not mean “high maintenance.” A well‑designed node can last 5–10 years and still count as zero‑maintenance within the lifecycle of many industrial systems.

3. Wired Sensors: Zero‑Maintenance for Continuous, High‑Frequency Monitoring

There are applications where real‑time, high‑resolution, continuous monitoring is required:

- seismic analysis

- vibration and modal analysis

- fatigue crack propagation

- early‑warning systems for critical infrastructure

- structural health under dynamic loads

In these scenarios, wired sensors remain the industry standard. They provide:

- stable power

- high data rates

- high bandwidth

- no ambiguity in timing

- continuous real‑time availability

Battery‑free and battery‑powered systems cannot match this performance envelope when the sensor must never lose coverage.

Zero‑Maintenance Is a Strategy, Not a Technology

The rise of zero‑maintenance sensors is not about replacing batteries everywhere. It’s about eliminating unnecessary maintenance using the architecture that best fits:

- the physics

- the environment

- the power geometry

- the update frequency

- the risk level

- the lifecycle costs

Battery‑free is transformative—especially in places where readers can reach the sensor, or where you can bring the reader (walk‑by, drive‑by, drone‑by).

Battery‑powered is essential where autonomy and distance matter.

Wired remains unbeatable for high‑bandwidth, real‑time demands.

At Kliskatek, our role is to help companies choose the right path—not the most fashionable one, but the one that will still be working a decade from now.